During a cupping in Cali, hosted by Juan Pablo Argote, I found one coffee that had many issues, but that I felt had potential to become something great. Ana Lucia Restrepo, who turned out to speak English quite well, recently returned to her parents’ coffee farm to continue their trade. She sees the need for investments and quality improvements, and is willing to put her shoulders to the wheel. Realizing this would be a very long-term project, with years of hard work to get this coffee to be recognized as a high-grade specialty coffee, I still felt inspired and energized to take action. The greying coffee production industry is a worldwide problem; this project may be the way to make things interesting again for new generations.

The value chain

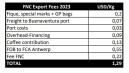

The infographic below shows what the monetary value chain with this producer roughly looks like. This changes slightly per year based on volume and quality but is usually reliable over the years.

After a successful trial last year, we decided to work together with the Colombian coffee federation as our export partner. Their costs are relatively low which allows us to pay Ana a price of USD 6.50/kg for her coffee. This is the goal that we aimed for when starting our collaboration; our first import from her only gave her USD 4.34/kg.

Key achievements

2018

June: first contact during a cupping in Cali. Started discussing the quality potential and how to start improving operations.

2019

March: first import of this coffee (490 kgs) with the help of Specials Coffee (dry mill), Amarella Cafe (exporter) and This Side Up (import advice).

June: first visit to this farm to get acquainted with the current way of working and the microclimate. Developed plans to improve operations and how to keep working together in the future.

2020

February: second import of this coffee (1152 kgs). Separate microlots for the Castillo and Cenicafe1 varieties. The Cenicafe1 lot was fully reserved for Tigershark Coffee.

June: purchased a moisture meter for Ana to help her standardize her drying process.

2021

May: third import of this coffee (1120kgs). First time using consolidated sea freight with the help of the Colombian Coffee Federation. This reduced costs and allowed us to pay Ana 50% more ($6/kg instead of $4/kg). Also, we succeeded in having the different plots of land processed separately. This made the roasting more consistent over the course of the year.

2022

Funded new drying beds with retractable shelves. This greatly improved the production space, but also the quality of and control over the drying process with better protection against rain and humidity.

The microlots

Together with Ana, we have tasted different coffees that she produces. She has planted different varieties, each with its own character, but all easy to maintain and highly resistant to leaf rust. The climate gives us similarities in flavour, but the different varieties are therefore even more exciting to taste along each other.

Nothing found.

Nothing found.

The project

During our conversations and when Ana shared pictures of her farm, we both noticed there was quite a lot to improve on. Coffee was still dried on wooden roofs, the fermentation chamber was worn-down, picking wasn’t as consistent as we would like… These issues are not easy to solve and it takes a lot of time and money. Still, Ana and I share a vision of this coffee becoming better every year by tackling one problem at a time and staying true to our promises. While working with her coffee, we try to identify the most important or most urgent issues so that those can be taken care of first.