Ana Restrepo Natural

Shokunin exclusive

After returning to her parents’ farm to continue the family trade, Ana Restrepo decided to transform her coffee into a specialty grade experience.

Region: Vereda Totoró, Sevilla, Valle de Cauca, Colombia

Altitude: 1,500 m.a.s.l.

Variety: Variedad Colombia

Processing: natural

Additional information

| Weight | N/A |

|---|---|

| Region | Vereda Totoró, Sevilla, Valle de Cauca, Colombia |

| Altitude | 1,500 m.a.s.l. |

| Variety | Castillo |

| Processing | Fully washed, 15 – 18 hrs fermentation |

| Flavour | Sweet and mellow aromas like marzipan. Smooth sweetness like honey and red apples. Heavy body like dark chocolate. |

Jelle's Notes

I first met Ana at a cupping in Cali that was organized by Juan Pablo Argote. Her coffee wasn’t yet at the level I needed, but it stood out from the table for its potential. Especially after we spoke, it was clear how driven she was to improve her farm and look ahead. That combination inspired me to start working with her.

The first time I visited her farm, in 2019, it gave me a clear picture of how she works and it was clear immediately that the approach I had developed with Argot could not simply be copied. Every farm has its own challenges, and with Ana we had to find solutions specific to her land and her processes.

Our collaboration started small, with just 200 kilos flown in by air freight. Over time, the volumes have grown to around 2400 kilos, still imported directly by Shokunin. Part of it I roast myself, and part I sell as green coffee to other roasters so Ana can scale up her exports. The rest of Ana’s harvest is sold locally. What began as a small experiment has now become a steady Shokunin exclusive.

Today Ana’s coffee shows exactly the kind of balance I look for. Where it once leaned heavily on pure chocolate with just a touch of fruit, it now brings a balanced mix of red fruit and dark chocolate. It is still a classic Colombian profile, with the structure and balance that make it so versatile. Since 2023 Ana has started producing a natural coffee, which keeps that classic base, but adds boozy sweetness on top. A little less clean, but full of character and a great addition to the range.

Producer

The value chain

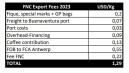

The infographic below shows what the monetary value chain with this producer roughly looks like. This changes slightly per year based on volume and quality but is usually reliable over the years.

After a successful trial last year, we decided to work together with the Colombian coffee federation as our export partner. Their costs are relatively low which allows us to pay Ana a price of USD 6.50/kg for her coffee. This is the goal that we aimed for when starting our collaboration; our first import from her only gave her USD 4.34/kg.

Key achievements

2018 June: first contact during a cupping in Cali. Started discussing the quality potential and how to start improving operations.

2019 March: first import of this coffee (490 kgs) with the help of Specials Coffee (dry mill), Amarella Cafe (exporter) and This Side Up (import advice).

June: first visit to this farm to get acquainted with the current way of working and the microclimate. Developed plans to improve operations and how to keep working together in the future.

2020 February: second import of this coffee (1152 kgs). Separate microlots for the Castillo and Cenicafe1 varieties. The Cenicafe1 lot was fully reserved for Tigershark Coffee. June: purchased a moisture meter for Ana to help her standardize her drying process.

2021 May: third import of this coffee (1120kgs). First time using consolidated sea freight with the help of the Colombian Coffee Federation. This reduced costs and allowed us to pay Ana 50% more ($6/kg instead of $4/kg). Also, we succeeded in having the different plots of land processed separately. This made the roasting more consistent over the course of the year.

2022 Funded new drying beds with retractable shelves. This greatly improved the production space, but also the quality of and control over the drying process with better protection against rain and humidity.

The microlots

Together with Ana, we have tasted different coffees that she produces. She has planted different varieties, each with its own character, but all easy to maintain and highly resistant to leaf rust. The climate gives us similarities in flavour, but the different varieties are therefore even more exciting to taste along each other.

The project

During our conversations and when Ana shared pictures of her farm, we both noticed there was quite a lot to improve on. Coffee was still dried on wooden roofs, the fermentation chamber was worn-down, picking wasn’t as consistent as we would like… These issues are not easy to solve and it takes a lot of time and money. Still, Ana and I share a vision of this coffee becoming better every year by tackling one problem at a time and staying true to our promises. While working with her coffee, we try to identify the most important or most urgent issues so that those can be taken care of first.

Key Achievements

2018 June: first contact during a cupping in Cali. Started discussing the quality potential and how to start improving operations.

2019 March: first import of this coffee (490 kgs) with the help of Specials Coffee (dry mill), Amarella Cafe (exporter) and This Side Up (import advice). June: first visit to this farm to get acquainted with the current way of working and the microclimate. Developed plans to improve operations and how to keep working together in the future.

2020 February: second import of this coffee (1152 kgs). Separate microlots for the Castillo and Cenicafe1 varieties. The Cenicafe1 lot was fully reserved for Tigershark Coffee. June: purchased a moisture meter for Ana to help her standardize her drying process.

2021 May: third import of this coffee (1120kgs). First time using consolidated sea freight with the help of the Colombian Coffee Federation. This reduced costs and allowed us to pay Ana 50% more ($6/kg instead of $4/kg). Also, we succeeded in having the different plots of land processed separately. This made the roasting more consistent over the course of the year.

2022 Funded new drying beds with retractable shelves. This greatly improved the production space, but also the quality of and control over the drying process with better protection against rain and humidity.

2024 First import of Ana’s natural processed coffee. Despite doubts due to environmental circumstances during the drying process, this coffee turned out great. We decided to upscale the natural lot in the coming years as far as the drying capacity allows.

2025 This year, the price Ana received for her coffee increased to $7.50/kg (a big increase over the $5.50 in the first year!), and the quantity increased to 2,500kgs (an increase of 400% over six years!)

Pricing

Price Breakdown

This coffee is special to Shokunin because it is imported personally. The relation to Ana started in 2018, and in 2019 we brought in our first direct shipment of just 350kg of coffee. Over time, the volumes increased, and with support from logistics partners, we were able to streamline the process.The goal has always been to pay Ana more for her coffee as the relationship developed and the quality improved. In 2025, the price per kg paid to Ana is more than double what it was in our first year working together.

€11.2

How is this built up?

$11.41

$12

€1.05